The story of Saveurs Santé

Its origins date back more than 30 years with the creation of a food processing company specializing in the design and manufacture of high-end ice cream desserts. Already at that time, quality and health were the fundamental elements of the company.

1989

Bélipacs Foundation specializing in frozen ice cream products

1999

Fondation de Gibiers d’Antan, a small farm specializing in game birds and varied market gardening, both certified “organic”. The products of culture and breeding are used for the needs of the gastronomic country table located in the ancestral house of the farm where we welcome many customers to make them discover an extraordinary culinary experience. Part of the production is also transformed into ready-to-eat products, such as cold meats, ready meals, etc.

Building on the experience acquired in research and development in addition to food processing, Bélipacs and Gibiers d’Antan gave birth to Aliments Saveurs Santé.

2005

Aliments Saveurs Santé Foundation specializing in the development and manufacture of ready-made meals for consumers and the food service industry.

The founders and managers of the company have a solid and extensive experience in food production and processing. The company is particularly recognized for its development of tailor-made products and its production capacity for large restaurant chains and specialty grocery stores.

Deep freezing

Deep freezing = Your guarantee of a fresher than fresh product!

Indeed, deep freezing respects the integrity of foods by freezing their optimal state in time just a few hours after their manufacture and by not altering any of their qualities, without requiring any preservative or stabilizer. .

At the time of tasting, the products are therefore at the peak of their freshness, taste and nutritional qualities.

Make no mistake, a fresh product begins to "age" right out of the box and all the way to your plate. Frozen products retain their nutritional qualities better and longer than fresh products. Frozen products have no time constraint forcing rapid use.

Quality control

From the choice of raw materials, through processing, packaging, freezing and distribution, we do everything we can to ensure the standardization and quality control of all products manufactured at our factory. .

In addition to the variety, originality, taste and repackaging of our products, quality remains our main priority.

We make sure that our products are made from exceptional raw materials, in optimal conditions to offer you the best product available in the market.

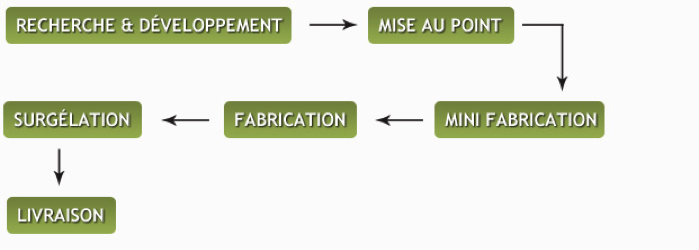

From creation to home

The creation of a product

Research & Development

Innovation is the first distinguishing element of the company. Indeed, our research and development team is constantly mobilized. The members of this team are curious gourmets and demanding consumers. First and foremost, we listen to our customers. All our products must undergo rigorous testing ranging from safety to ease of repackaging for the customer. Our range of products is constantly updated with current tastes while ensuring that timeless classic dishes are kept on the menu.

Focus

The development process is characterized by interactive cycles in order to obtain a product in all respects in accordance with the established objective. Several elements are taken into account, including taste, texture, appearance before freezing and also when repackaging, whether in a conventional oven or in the microwave.

Mini fabrication

This stage is characterized by the development and fine-tuning of production sheets in order to ensure volume production capacity while respecting the fundamental qualities of the product developed. It's also during this step that we make the very last adjustments to the recipe.

Manufacturing

Although we have a large production capacity, all the steps are on a human scale and do not involve production lines without human contact. This approach allows for a great flexibility in production, ensuring our ability to cook all products in all their diversity.

Freezing

This is the stage where we seal the freshness of the cooked food until the stage of its consumption at home. This allows us to assure you that no preservatives are added to the food we cook. We have always considered that these products were useless and harmful to health, so why consume them when modern technology allows us to do without.

Delivery

Here we are at the last step and not the least since it allows you to taste our delicious products without having to go anywhere. We have developed a specialized packaging that allows us to maintain the Health Flavors products in optimal conditions. Thanks to this process, we deliver everywhere in the province of Quebec.

Saveurs Santé factory

The Saveurs Santé factory is located in l'Assomption. With a surface area of 10,000 square feet, we have three processing departments whose infrastructure meets the standards established by the MAPAQ (Ministère de l'Agriculture, des Pêcheries et de l'Alimentation du Québec). We also have a research and development and quality control laboratory. Our factory is under provincial inspection.

Among our "Food Service" clients, we count Bistros Van Houtte, Café Dépôt, Groupe Épicia, Les Sommets ski centers, Centre Hospitalier Le Gardeur as well as Rôtisseries Duhamel, just to name a few.

From appetizers to desserts, we make all your delicacies while ensuring that we meet the quality standards we have established.